Integrity

Capabilities

Launcher, receiver & ILI integrity projects

Valve & control valve replacement projects

Pipe stress analysis

Flange leak analysis

Buoyancy assessment

Line segment replacement

Finite element analysis (FEA)

Modal and harmonic analysis for mechanical piping skid design

Equipment nozzle loads

Limit states piping design using Abaqus or Ansys

Fatigue assessment under high cycled vibration

HDD crossing design (river crossing, pipeline crossing, etc.)

Time transient analysis (slug flow, water hammer, etc.)

Previous Projects

-

Launcher and Receiver Stress Analysis

Lanmark provided design and engineering of a launcher and receiver on the 24” Nevis-Gadsby crossover, creating a 80.2 km long piggable pipeline section.

This involved creating a FEA model and performing stress analysis of the crossover 24” scraper trap, 8” valve assembly, and associated piping. Lanmark evaluated the launcher scraper trap piping and underground piping to ensure all stress levels, forces, and displacements are within code allowances.

Project details:

Systems were designed to CSA Z662-11, SOR/99-294, CSA C22.3 No.6-M91

Flange leakage calculations designed per ASME Section VIII Div 2 criteria

Membrane stress at support locations were checked and suitable pipe support locations were recommended as required

-

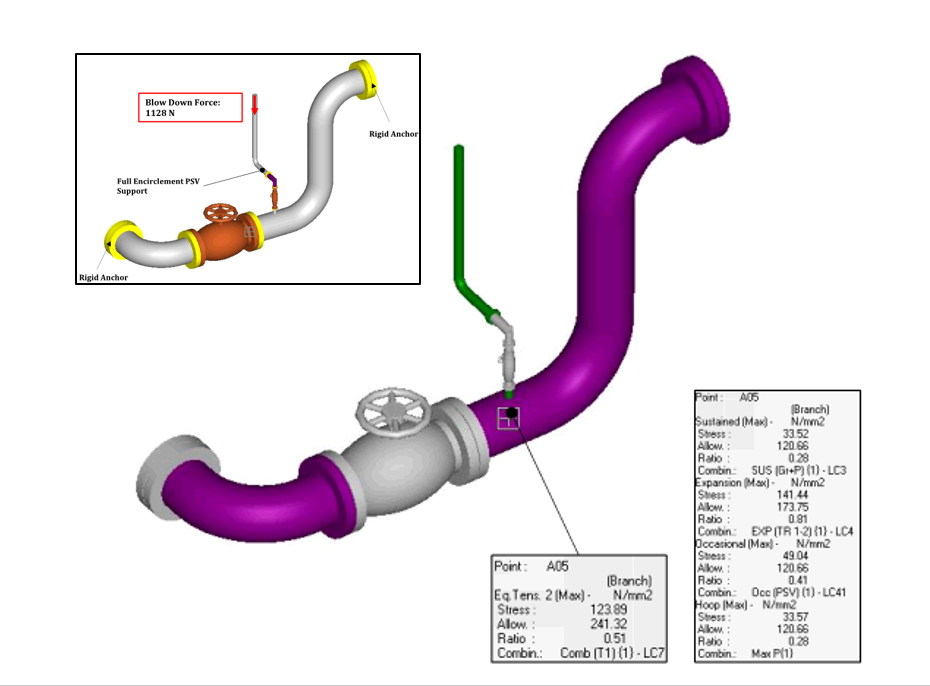

RMS Stress Analysis

Lanmark conducted a stress analysis on the addition of a PSV assembly to a NPS 12 sour gas pipe run per CSA Z662.

Project details:

Static and dynamic loads and stresses of the assembly were reviewed and how it affected the new assembly on the existing piping

performed a flange leakage check as per ASME BPV section VIII Div 1 and Div 2

-

NPS 42 Launcher Stress Engineering

Lanmark engineered a NPS 42 launcher at the NPS 30 & 42 Paul Lake Crossover Phase 1 site.

Project details:

Conducted stress analysis for the new launcher

Assessed impact of the new installation on pre-existing pipeline and tie-ins

Assessed the associated piping support loads